Working on an AR that somebody had no idea how to build

Ron Gunner 10.03.18

Have you ever worked on an AR that you bought used or one for friend only to find out that it was built by someone that should have never tried to build one? I have in the past, a total of 2 times. This last one was the worse. This one was a mess to work on and a simple job took much longer than it should.

This was a complete rifle from Del-ton and had been worked on before. I was asked to put a new floating handguard on it. I agreed to do it and they wanted me to make the low gas block out of the original sight. That was not an issue, cut the lugs off and cut the upper sight off on each end and file down.

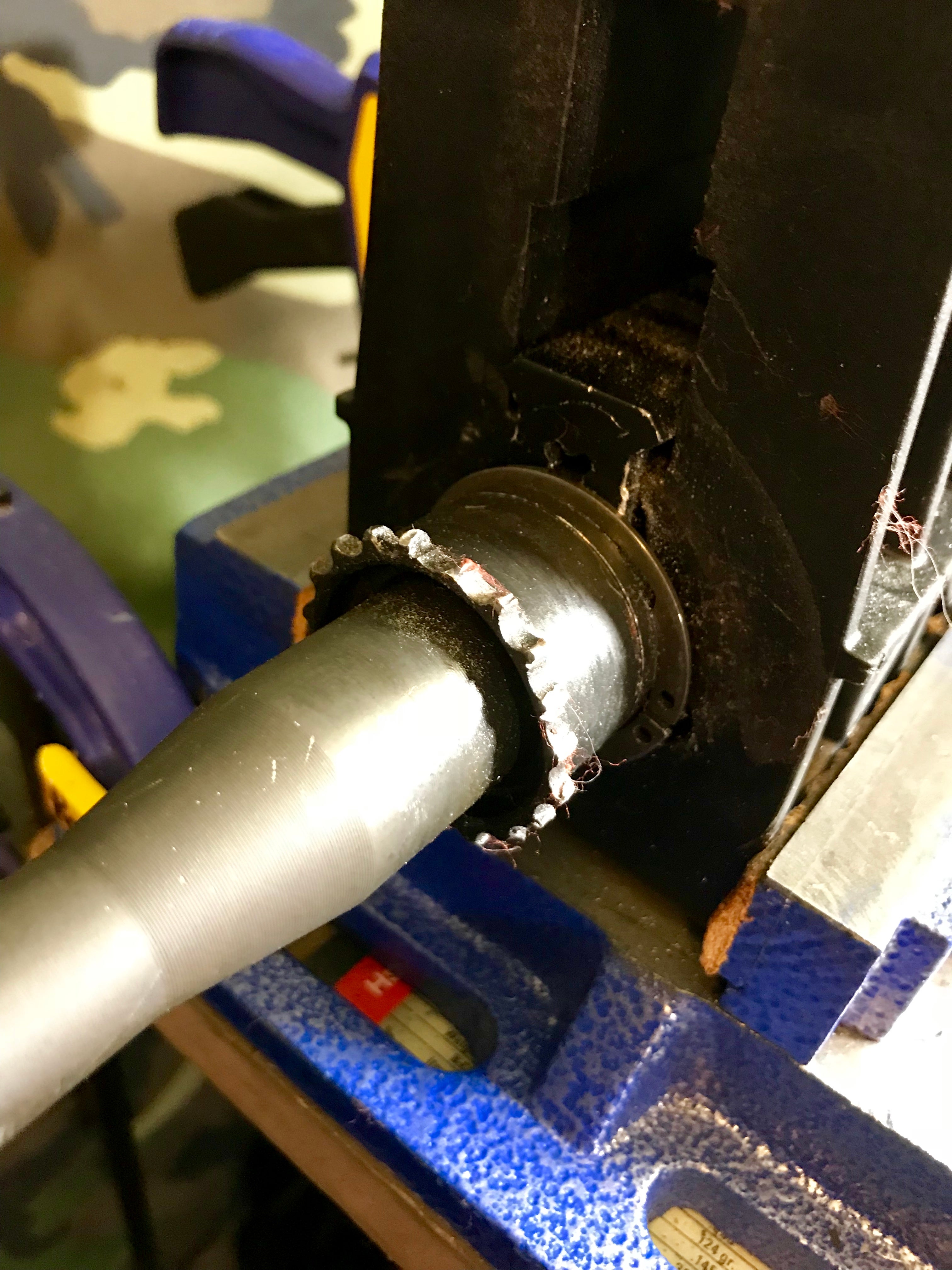

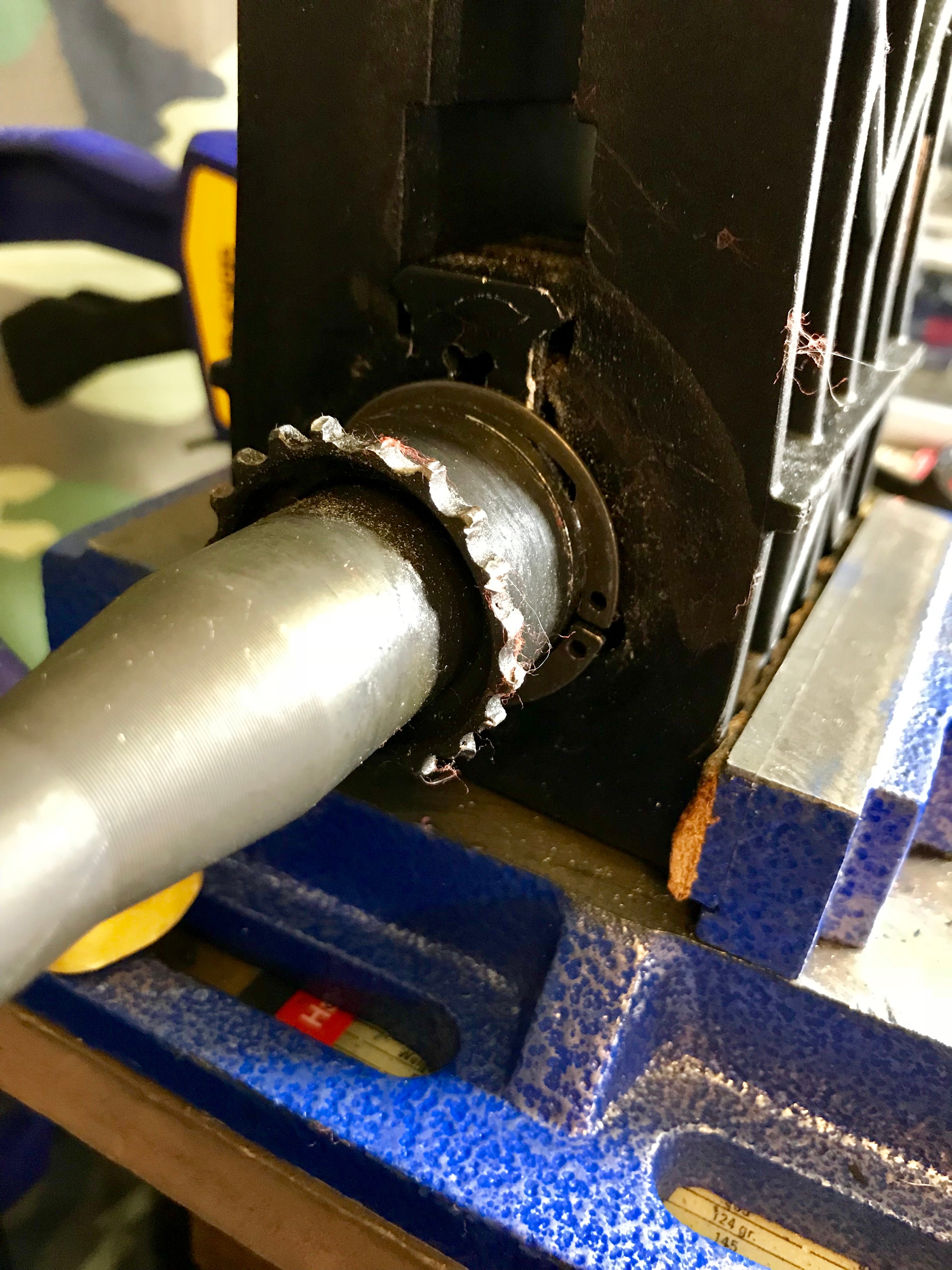

Then it came time to remove the barrel to install the new barrel nut that came with the floating handguard. I locked it in the AR upper receiver block and put it in the first vise. It was a vise from Lowes that I have used many times in the past. During the process of trying all of this, at some point the vise cracked. So I had to break out my drill press vise and clamp it on the table by quick clamps and move on.

I was VERY surprised that this vise held up during all of this work to get the AR barrel nut off. I broke the “lugs” off the barrel nut and then even the studs off my AR barrel nut wrench. I tried everything I had at the bench to get this done. I had to end up cutting off the delta ring and pulling apart the spring behind it. I had to do all this to get the barrel nut so I could try a few more things.

Even the old bar style torque wrench bent and was off the scale trying to get this to break free, over 100 foot pounds of pressure. I couldn’t believe it; a friend of mine who has built over 100 AR’s stopped by and was shocked.

I tried overnight soaking with PB Blaster, Ballistol, you name it. Heating up the nut didn’t work with any wrench I had until I had to dig out the BIG pipe wrench from the garage that hadn’t been used for anything since the late 1970’s. With this little vise and how it was mounted, I had to turn the wrench around to be able to use it.

Finally the BIG wrench with heat and PB Blaster broke it free. Once that happened it turned trouble free with your fingers. I checked the upper and nothing bad had happened to it. The issue, best I could figure out, was that there was NO anti-seize or grease at all anywhere on the barrel or nut. It looked like it was sonic cleaned it was so dry! Plus the unholy amount of torque by whomever installed this AR barrel.

If you don’t build it yourself, you never know what you will run into!

Stay safe and see you out there!

R Gunner